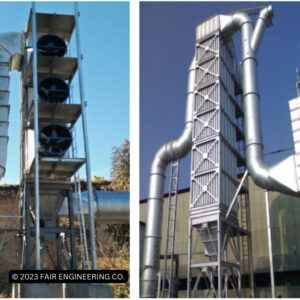

A pneumatic multi-louver damper is a device used to control the flow of air inside the ducting system. This device consists of a series of panels with adjustable louvers which can open or close depending on the pressure of the air passing through them. By adjusting the louvers, the amount of air passing through the ducting system can be regulated. This device is widely used in ducting of pollution control systems, HVAC (heating, ventilation, and air conditioning) industry.

Description

A pneumatic multi-louver damper is a device used to control the flow of air inside the ducting system. This device consists of a series of panels with adjustable louvers which can open or close depending on the pressure of the air passing through them. By adjusting the louvers, the amount of air passing through the ducting system can be regulated. This device is widely used in ducting of pollution control systems, HVAC (heating, ventilation, and air conditioning) industry.

Function of the Pneumatic Multi Louver Damper

The primary function of the pneumatic multi-louver damper is to control the flow of air inside the ducting system. By adjusting the louvers, the amount of air passing through the system can be regulated. This can help in maintaining a specific set point temperature as well as regulating the amount of air passing through the system. This can also be used to minimize noise levels as well as reduce the energy consumption associated with running the system.

Advantages of the Pneumatic Multi Louver Damper

One of the main advantages of the pneumatic multi-louver damper is its cost-effectiveness. This device is relatively inexpensive compared to other types of dampers. Additionally, it is relatively easy to install and maintain. The device is also relatively quiet and energy-efficient, making it a great choice for applications where energy savings are a priority.

Conclusion

The pneumatic multi-louver damper is a cost-effective and energy-efficient device used to control the flow of air inside the ducting system. This device is relatively easy to install and maintain, and can help in maintaining a specific set point temperature as well as reducing noise levels and energy consumption. However, it has its limitations and is not suitable for applications requiring high levels of air pressure.