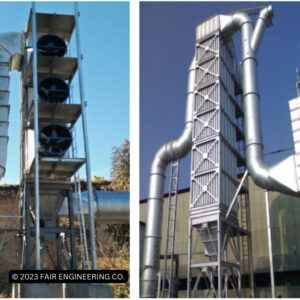

The rotary air lock valve with geared motor is a versatile industrial component used in a variety of applications. It is a type of valve that regulates the flow of material from industrial hoppers, while allowing the material inside the hopper to be dispensed. The rotary air lock valve is a critical component for many industries that transfer dust or powder in a regulated flow, such as in steel plant air pollution control systems agricultural, pharmaceutical, and mining operations.

Description

The rotary air lock valve with geared motor is a versatile industrial component used in a variety of applications. It is a type of valve that regulates the flow of material from industrial hoppers, while allowing the material inside the hopper to be dispensed. The rotary air lock valve is a critical component for many industries that transfer dust or powder in a regulated flow, such as in steel plant air pollution control systems agricultural, pharmaceutical, and mining operations.

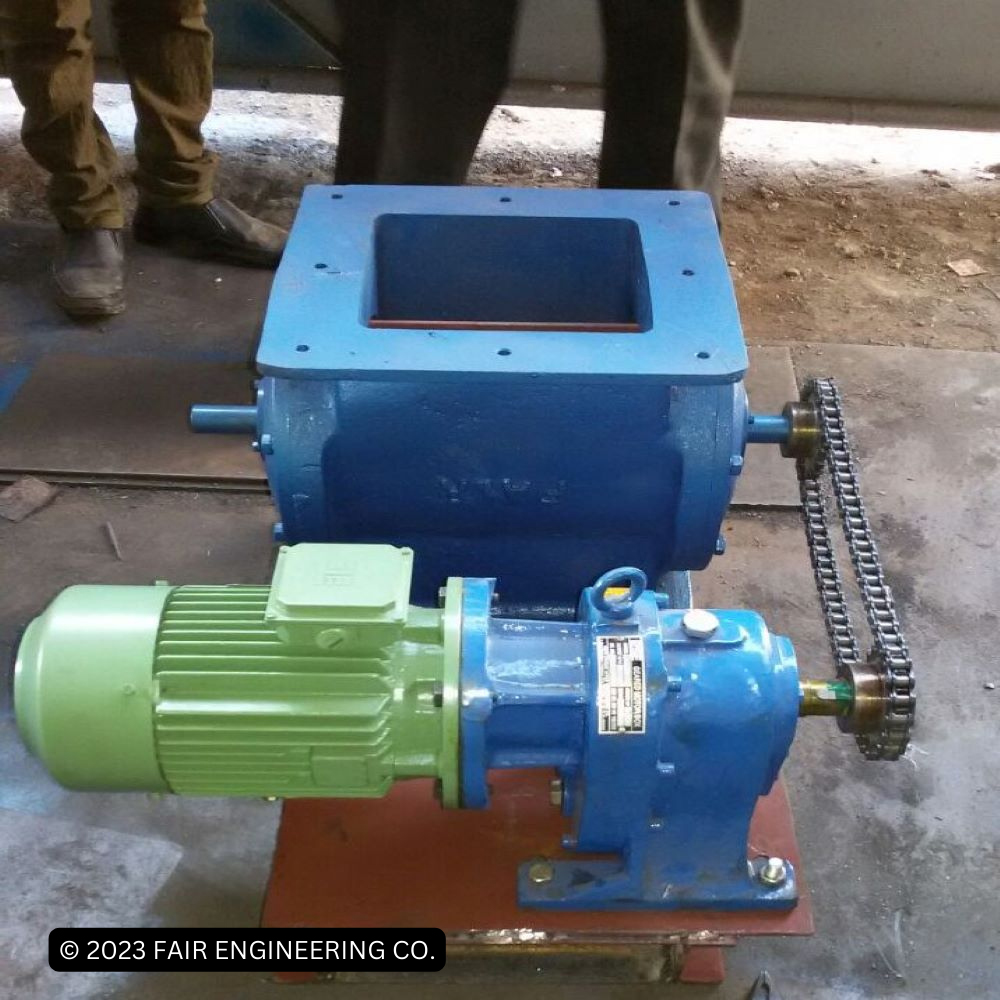

The rotary air lock valve consists of a cylindrical housing that contains a rotating disk. The disk contains four blades, which rotate in order to regulate the air flow and pressure inside and out of hopper. The rotating disk is connected to an external geared motor, which is used to control the speed of the disk’s rotation. This allows for precise control over the amount of material dispensed from the hopper.

The rotary air lock valve with geared motor is an efficient and effective way to transfer dust or powder from one chamber to another. It minimizes dust loss and spillage, and its precise control over material flow helps to optimize dispensing methods. The rotary air lock valve can also be used to prevent air from entering a chamber, which is essential for certain industrial processes that require a dust-free environment.

It is durable and reliable component that can be used in many applications. It is easy to install and maintain, and it is also resistant to wear and tear. It is an essential component for many industries that need to transfer dust or powder in a controlled way thereby reducing spillage of materials.