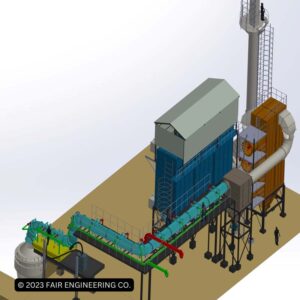

In Air pollution control system, the most important factor is the volume of fumes, fume temperature and fume velocity. The more hotter and dense air requirements for high velocity of suction, also increases. Hence its important to reduce the fume temperature to safeguard filter bags and other electronic/electrical equipment’s. To reduce the fume temperature, we install water cooled ducting, cyclone and various equipment’s.

Description

In Air pollution control system, the most important factor is the volume of fumes, fume temperature and fume velocity. The more hotter and dense air requirements for high velocity of suction, also increases. Hence its important to reduce the fume temperature to safeguard filter bags and other electronic/electrical equipment’s. To reduce the fume temperature, we install water cooled ducting, cyclone and various equipment’s.

The Process

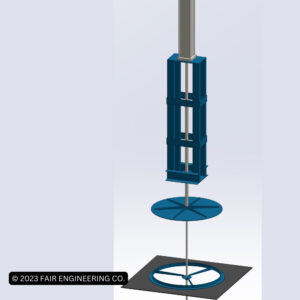

Water cooled 90 ° Bends used to transfer hot fumes from furnace to baghouse. During the steel melting process, the furnace fume temperature can reach up to 1200 °C. These fumes contain poisonous chemicals, metal particles and various materials in ash form.

Fair Engineering fume extraction system works at temperature of max 140 °C thereby providing good quality air filtration without any damage to filter bags. The FES process includes cooling down fumes from 1200 °C to 140 °C by using water cooled ducting system, spark arrestor, dilution dampers and various equipment’s. The fumes are later passed down from bag filter system after attaining optimum temperature of 140°C for effective filtration.