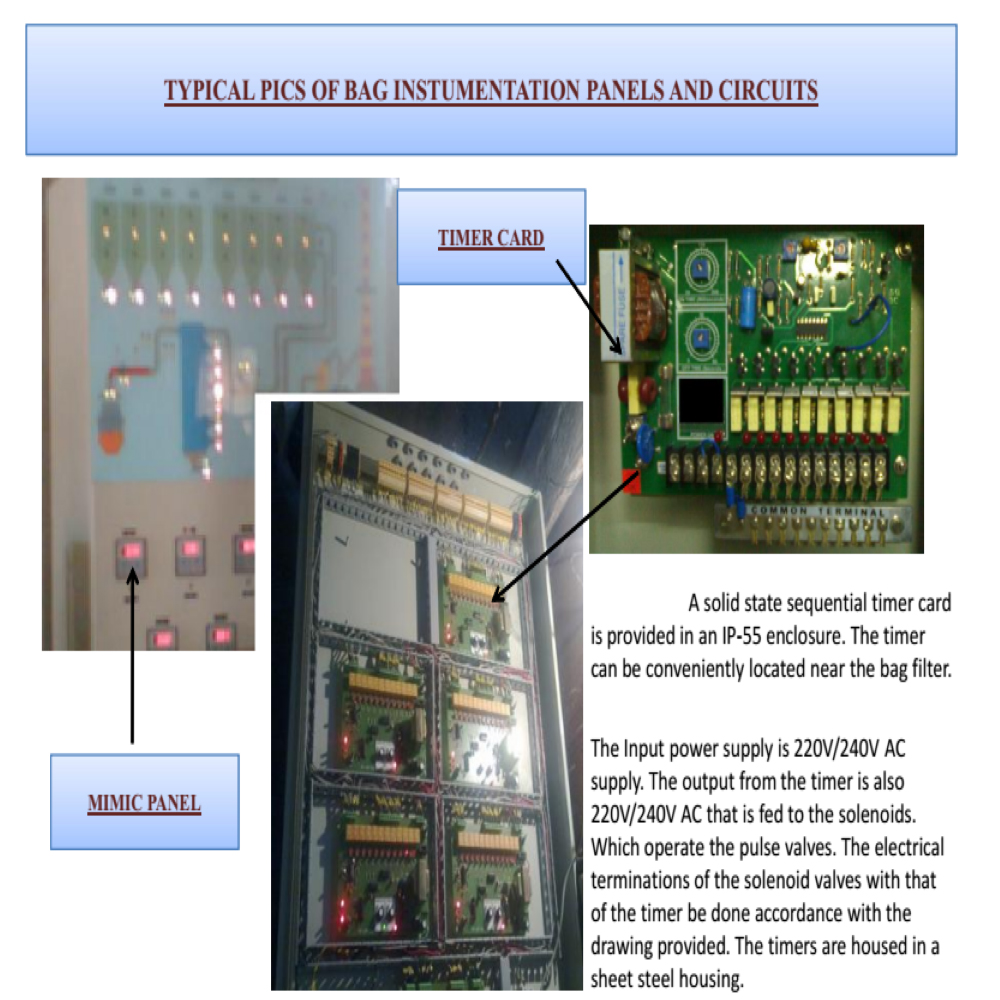

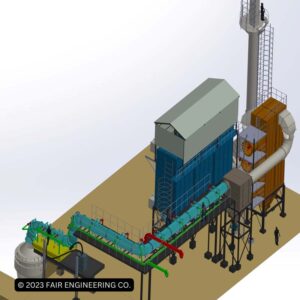

Fair Engineering Co. is pioneer is automation of FES system. All automation work is done inhouse by qualified engineers and commissioned at site by FEC team. We use the latest FEC designed timer card, MIMIC panels and branded configured VFD drives for all our electrical components such as geared motors, solenoid coils used for pulsing valves and pneumatic cylinders etc.

Description

Fair Engineering Co. is pioneer is automation of FES system. All automation work is done inhouse by qualified engineers and commissioned at site by FEC team. We use the latest FEC designed timer card, MIMIC panels and branded configured VFD drives for all our electrical components such as geared motors, solenoid coils used for pulsing valves and pneumatic cylinders etc.

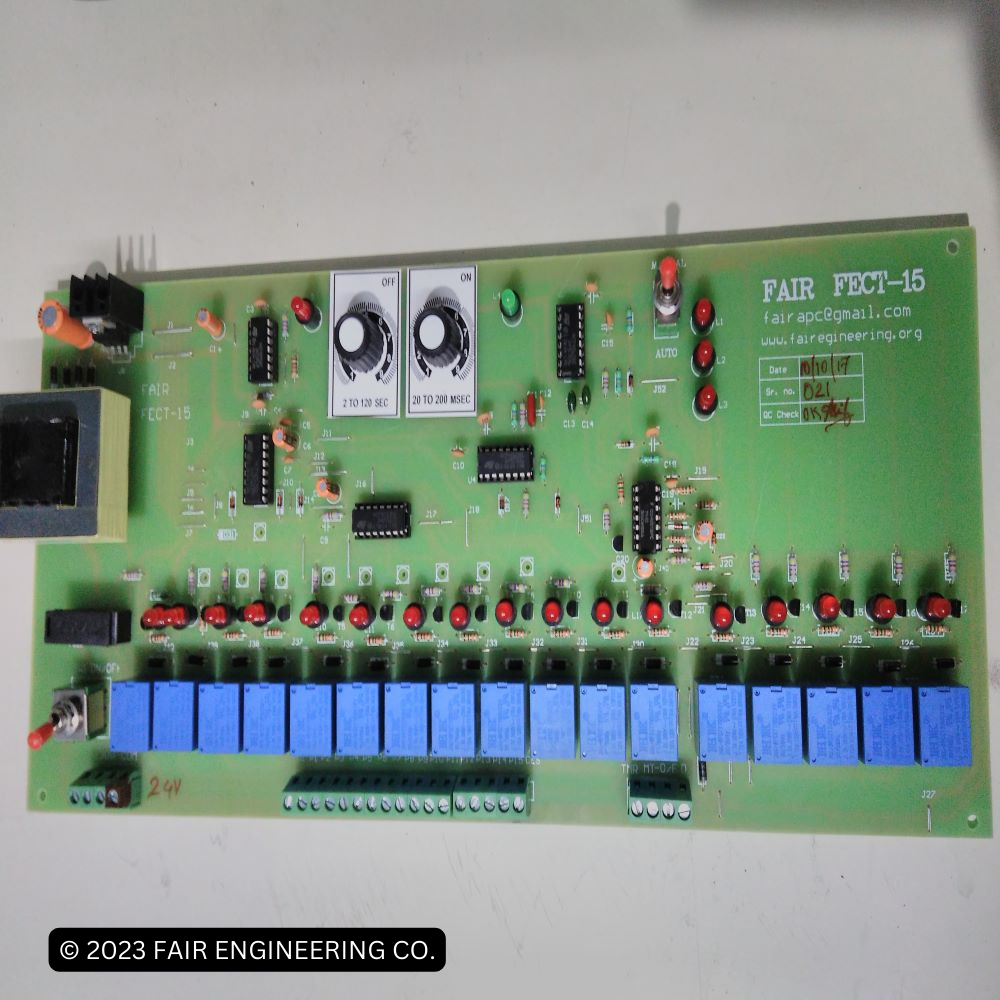

A solid-state sequential timer card is provided in IP-55 enclosure. The timer can be conveniently located near the bag filter. The input power supply is 220V/240V AC supply. The output from the timer is also 220V/240V AC that is fed to the solenoids which operate the pulse valves. The electrical terminations of the solenoid valves with that of the timer be done accordance with the drawing provided. The timers are housed in a sheet steel housing.

Understanding FEC Variable Frequency Drives for Electric Motors

Variable frequency drives (VFDs) are electronic controllers that can vary the speed of an electric motor by controlling the frequency and voltage of the power supplied to the motor. They enable precise control of motor speed and torque, which can provide several potential benefits to the user.

In this article, we will explore the benefits and drawbacks of using a VFD for electric motor control, and examine the components of a VFD system and how they are used to control the motor.

Benefits of Using a VFD

One of the biggest advantages of using a VFD to control an electric motor is that it can improve energy efficiency. By controlling the speed and torque of the motor, the VFD can reduce the amount of energy used during each cycle. This can reduce energy costs and save money in the long run.

Another advantage is that the VFD can provide dynamic control of the motor, allowing it to adjust its speed and torque as needed to meet changing conditions. This can provide greater flexibility and control over the motor’s operation.

Finally, VFDs can provide smoother starts and stops, reducing the amount of wear and tear on the motor and extending its useful life.

Components of a VFD System

A VFD system typically consists of three main components: the inverter, the motor, and the control panel. The inverter converts the incoming AC power into a DC signal, which the motor then uses to generate rotational force. The control panel is used to set the frequency and voltage of the power supplied to the motor, which in turn changes the speed of the motor.

Conclusion

VFDs can provide a number of benefits for electric motor control, including improved energy efficiency, dynamic control of the motor, and smoother starts and stops. However, they can also be expensive and require a more sophisticated level of maintenance than other solutions.