To control air pollution emanating from AOD furnaces, use an appropriate air pollution control system which includes devices such as scrubbers, baghouses, or electrostatic precipitators, cyclones, high efficiency blowers to capture and remove pollutants from the furnace exhaust. The use of most appropriate filter media can help reduce the amount of dust and particulate matter in the exhaust.

Description

To control air pollution emanating from AOD furnaces, use an appropriate air pollution control system which includes devices such as scrubbers, baghouses, or electrostatic precipitators, cyclones, high efficiency blowers to capture and remove pollutants from the furnace exhaust. The use of most appropriate filter media can help reduce the amount of dust and particulate matter in the exhaust.

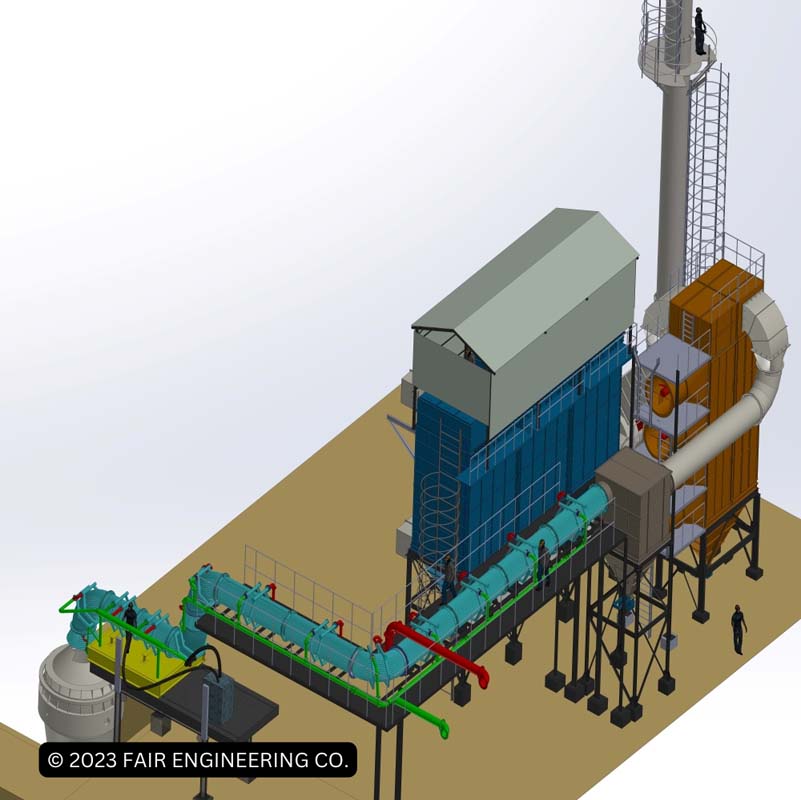

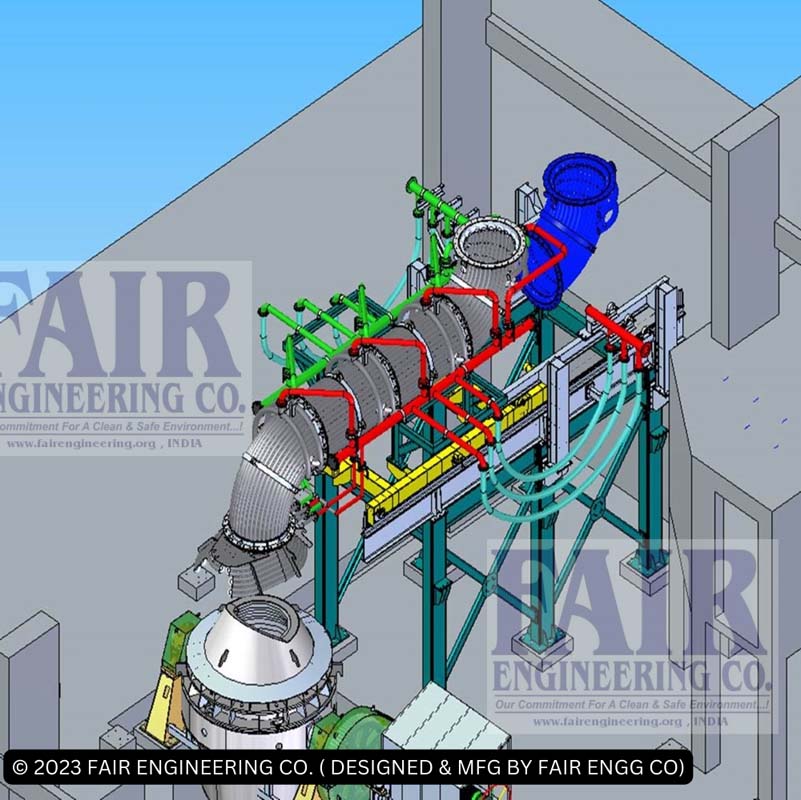

Fair Engineering Co. (FEC’s) designed FES system is useful to capture high temperature fumes emanating from AOD by placement of the water-cooled primary hood provided over the AOD vessel. Water-cooled ducting is provided to channelise the fumes to bag filter system. To help in movement of Overhead crane, pouring of molten metal from ladle the furnace needs to be tilted often, hence FEC has designed moveable hood and ducting on trolley, thereafter a fixed water-cooled duct with a fixed specified gap between secondary hood elbow flange and duct is made to facilitate fume suction. The water-cooled ducting can be of double walled or tubular design types.

During AOD working process the exhaust fume temperature is about 1200°C which needs to be cooled down up to 140°C. The dust concentration in the fume is in the order of 2 to 3g/Nm3. The initial fumes coming out from the AOD will be cooled down by water cooled ducting, later it will be cooled down by Forced Draft Cooler (FDC) to suit the temperature for filter bags and protect them from burning. Once the desired temperature reduction is achieved, the fumes will be directed towards bag filter and then fumes will get filtered up to concentration level of less than 50mg/Nm3

Finally, proper maintenance of the air pollution control system is essential for ensuring the system is working properly and providing adequate air pollution control. This includes regular cleaning of the system components, regular testing, and replacement of worn parts, as well as scheduled maintenance of all components.

In conclusion, air pollution control from AOD furnaces is an important process that requires careful attention, as many of the pollutants released by these furnaces are hazardous to human health. By ensuring the FES system is properly maintained and by upgrading system spare parts after service life, can help reduce the amount of air pollution produced by AOD furnace.