Submerged arc furnaces are used in steel plants to melt and convert raw materials into steel. The process produces a large number of fumes and other hazardous gases, which can cause serious air pollution if not managed properly. To address this issue, many steel plants have implemented a fume extraction system, which captures and filters out the fumes before they can be released into the atmosphere.

Description

Submerged arc furnaces are used in steel plants to melt and convert raw materials into steel. The process produces a large number of fumes and other hazardous gases, which can cause serious air pollution if not managed properly. To address this issue, many steel plants have implemented a fume extraction system, which captures and filters out the fumes before they can be released into the atmosphere.

The fume extraction system works by drawing in air contaminated with fumes and other hazardous gases and then passing it through a series of filters. This process removes harmful particles from the air, allowing only clean air to be released back into the atmosphere. The filters used in the system must be carefully chosen to ensure that they are capable of removing the specific types of particles found in the fumes generated by the furnace.

The system also has a fan which helps to increase air flow and speed up the process of extracting the fumes. The fan is designed to run at a low speed, ensuring that the air is being filtered properly, and also helps to reduce the noise generated by the process. Additionally, the fan helps to keep the temperature in the furnace consistent, which helps to ensure that the melting process is running smoothly.

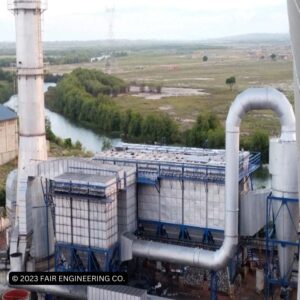

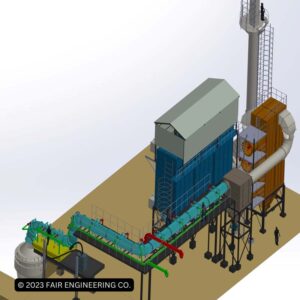

Fair Engineering Co. (FEC’s) designed SAF-FES system which is useful to capture high temperature fumes emanating from around the SAF electrodes which are sucked from the furnace sideways with the side hoods as shown in the diagram. Water-cooled ducting is provided to convey the fumes. The water-cooled ducting can be of double walled or tubular. The tubular ducting will have longer life as proper water conveying velocities can be maintained as there will be no short circuiting of water unlike in the double walled water-cooled ducts. It is necessary to have treated cooling water circulation in water-cooled circuit. The water must be treated for TSS, TDS and hardness etc.

During extracting of the fumes, it contains very high temperature which needs to be cooled down. The dust concentration in the fume is in the order of 2 to 3g/Nm3. The initial fumes coming out from the AOD will be cooled down by water cooled ducting, later it will be cooled down by Forced Draft Cooler (FDC) to suit the temperature for filter bags and protect them from burning. Once the desired temperature reduction is achieved, the fumes will be directed towards bag filter and then fumes will get filtered up to concentration level of less than 50mg/Nm3.

The fume extraction system is an important part of any steel plant, and it is essential that it is maintained and operated properly in order to ensure that the emissions are kept within acceptable levels. By doing so, steel plants can help to reduce the amount of air pollution that is released into the atmosphere, thus contributing to a cleaner and healthier environment.