Induction furnaces are an important part of the steelmaking process, as they allow steel producers to quickly and efficiently melt down scrap metal and ore. However, induction furnace processes can produce fumes that can contain dangerous pollutants, necessitating the use of hoods for fume collection and cleaning. In this article, we will discuss the induction furnace process, the types of pollutants present in the fume exhaust, and the different hoods available for fume collection and cleaning.

Description

Induction furnaces are an important part of the steelmaking process, as they allow steel producers to quickly and efficiently melt down scrap metal and ore. However, induction furnace processes can produce fumes that can contain dangerous pollutants, necessitating the use of hoods for fume collection and cleaning. In this article, we will discuss the induction furnace process, the types of pollutants present in the fume exhaust, and the different hoods available for fume collection and cleaning.

Induction Furnace Processes

Induction furnace processes involve heating metal ore or scrap by passing an electrical current through it. The electrical current creates an electromagnetic field which induces eddy currents in the metal, producing intense heat in a short amount of time. The process requires precise temperature control, careful monitoring of the furnace’s power input, and the periodic addition of fluxing agents.

The induction furnace process is typically used to melt scrap metal and ore for the production of steel and other alloys. Induction furnaces are capable of reaching temperatures of up to 2,500°C, much higher than other furnace types, allowing for the production of a wide range of steels and alloys. The induction furnace process is significantly more efficient than other types of furnace processes, allowing for rapid cooling and production of high-quality steel.

Pollutants in Fume Exhaust

The induction furnace process produces a significant amount of fume exhaust, which can contain a number of dangerous pollutants. The contaminants in the exhaust can include particulate matter, such as smoke and dust, as well as toxic chemicals and heavy metals. Particulate matter can be dangerous to humans when inhaled, while toxic chemicals and heavy metals can cause long-term health effects.

In order to protect workers and the surrounding environment from these pollutants, it is necessary to collect and clean the fume exhaust. This can be done with the use of hoods, which are designed to capture and contain the exhaust before it is released into the environment.

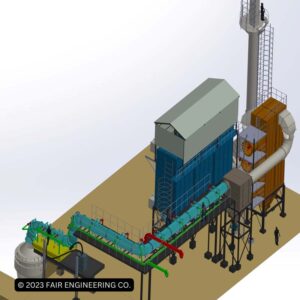

Fair Engineering Co. (FEC’s) designed Ind-FES system which is useful to capture high temperature fumes emanating from Induction furnace which are sucked from the furnace via canopy hoods or side draft hoods.

During extracting of the fumes, it contains very high temperature which needs to be cooled down. The dust concentration in the fume is in the order of 2 to 3g/Nm3. The initial fumes coming out from the AOD will be cooled down by water cooled ducting, later it will be cooled down by Forced Draft Cooler (FDC) to suit the temperature for filter bags and protect them from burning. Once the desired temperature reduction is achieved, the fumes will be directed towards bag filter and then fumes will get filtered up to concentration level of less than 50mg/Nm3.

Finally, proper maintenance of the air pollution control system is essential for ensuring the system is working properly and providing adequate air pollution control. This includes regular cleaning of the system components, regular testing, and replacement of worn parts, as well as scheduled maintenance of all components.