The primary fumes of LRF are sucked from the water-cooled elbow provided on its 4th hole. Water-cooled ducting is provided to convey the fumes. A suitable water-cooled moving sleeve or alternatively a fixed water cooled duct with a fixed specified gap between elbow flange and duct can be made to facilitate the LRF roof movements. The water-cooled ducting can be of double walled or tubular.

Description

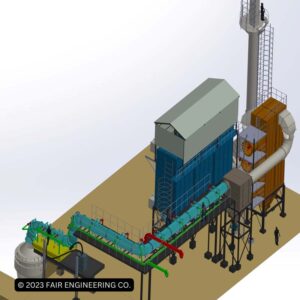

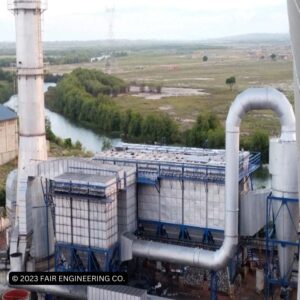

The primary fumes of LRF are sucked from the water-cooled elbow provided on its 4th hole. Water-cooled ducting is provided to convey the fumes. A suitable water-cooled moving sleeve or alternatively a fixed water cooled duct with a fixed specified gap between elbow flange and duct can be made to facilitate the LRF roof movements. The water-cooled ducting can be of double walled or tubular. The tubular ducting will have longer life as proper water conveying velocities can be maintained as there will be no short circuiting of water unlike in the double walled water cooled ducts. It is necessary to have treated cooling water circulation in water-cooled circuit. The water must be treated for TSS, TDS and hardness etc. During extracting the fumes it contains very high temperature which needs to be cooled down . The initial gas coming out from the LRF will be cooled down by water cooled ducting. After wards it will be cooled down by Forced Draft Cooler (FDC)/ Gas cooler to suit the temperature for fabric filters Now transporting the fume to bag filter and filter the same to a concentration level of less than 50mg/Nm3 (or as per the norms given by client). The dust concentration in the fume is in the order of 2 to 3g/Nm3. The coarse particle content is less than that of fine particles that are more and all that is fume. `

The gas cooler is then followed by a pulse jet bag filter or set of bag filter Inside the bag filter, cylindrical bags made of polyester / special material (as per required in the application) are intercepted in the flow path of air and the particles are collected onto these filters by mechanisms interception, inertial impaction and diffusion. The pulse jet collector is continuous automatic filter capable of filtering dust laden air through a felted non-woven filter media.

The bag filter is followed by a centrifugal fan which generates the driving force in the system and creates negative pressure which causes suction of fumes. The clean air from the bag filter is being discharged by ID fan/Centrifugal fan and vented to same to atmosphere through chimney.